首頁

>

產品分類

>

溫度/壓力/應力及校正

>

TEAC

>

多彩觸控螢幕數位指示計

產品分類

Products

多彩觸控螢幕數位指示計

chevron_right

- 兩通道輸入, 可以連接荷重元或位移計.

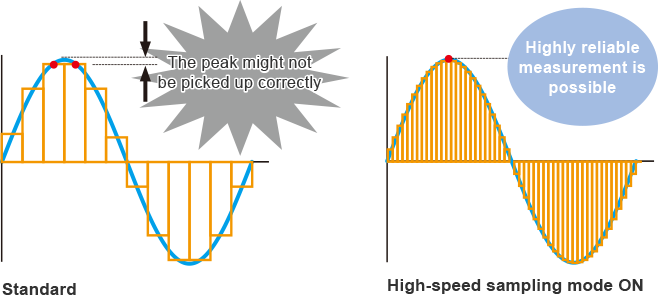

- 高速 A/D 轉換 25,000 次/秒

- 4.3英吋 觸控螢幕

- 尺寸 DIN1/4 (92 x 92)

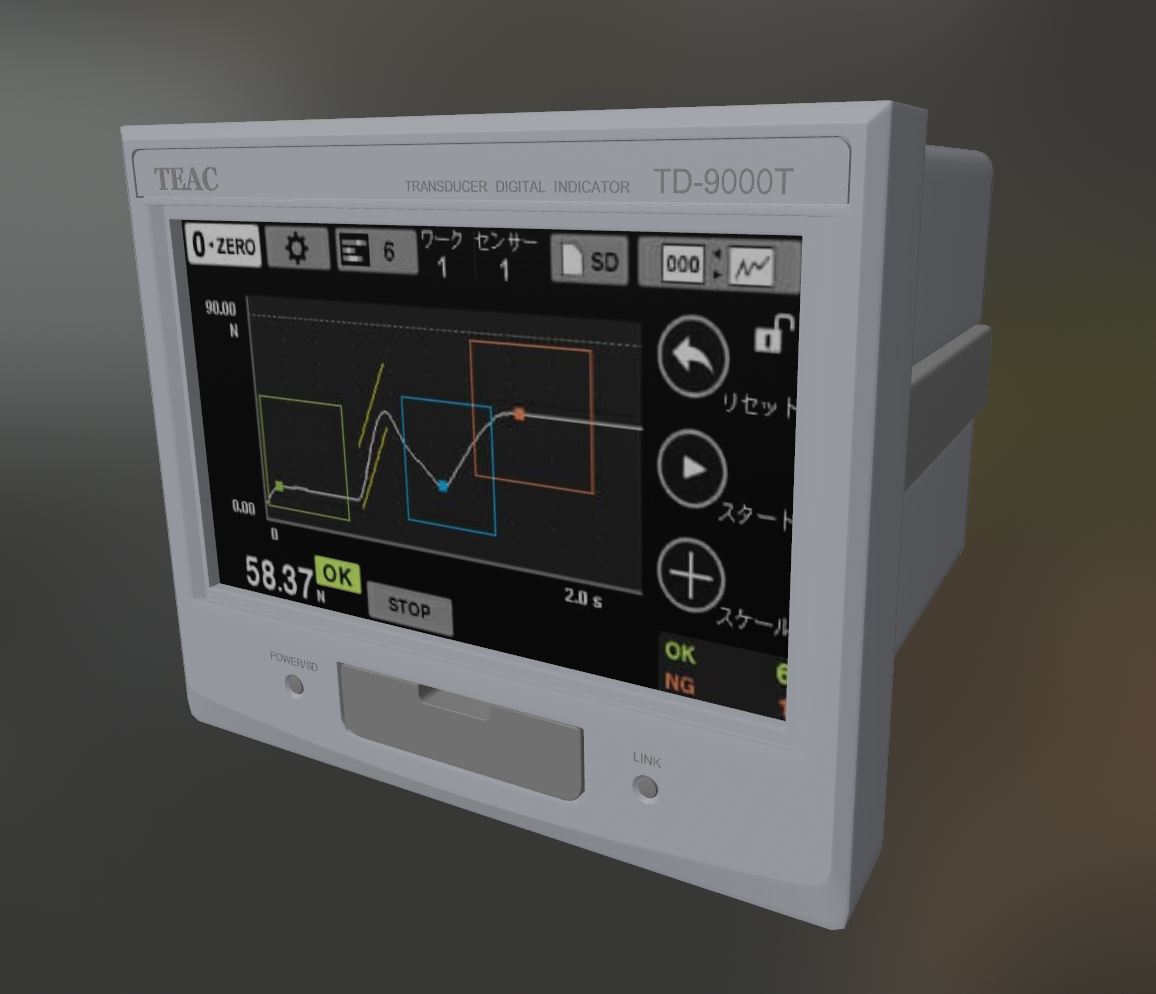

The TD-9000T is a digital indicator for load management that supports two inputs, load (load cell) and stroke (displacement gauge).

High-speed A/D conversion of 25,000 times/sec and equipped with a 4.3-inch touchscreen monitor in DIN1/4 (92 x 92) size. While being high-end, it is a high-performance model that realizes a low price.

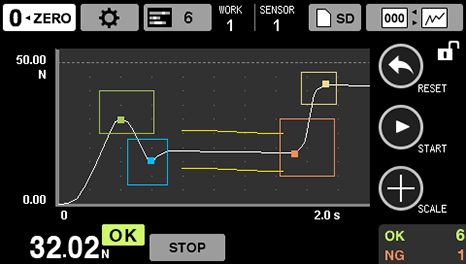

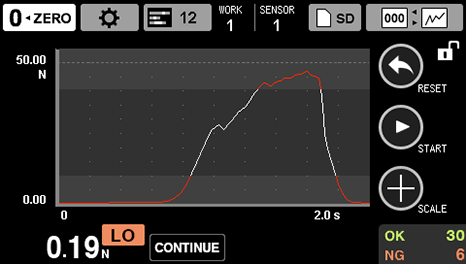

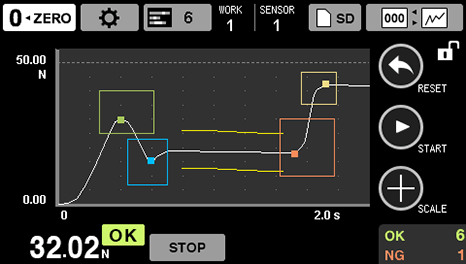

Waveforms during measurement can be checked in real time. Widely usable from daily monitoring to verification of processing data.

System configuration

Press loading control of press fitting

Measuring key-touch force when pressed

Specifications

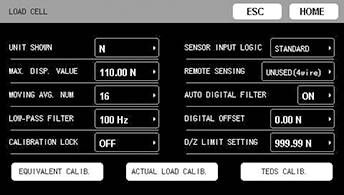

Sensor input

| Bridge Voltage | 2.5V / 5V / 10V ±10%(30mA current maximum, remote sense can be used) | |

|---|---|---|

| Signal input range | Strain gauge sensor -3.2mV/V - 3.2mV/V | |

| Calibration | Calibration range | 0.1mV/V - 3.2 mV/V |

| Calibration method | Equivalent Input / Actual Load / TEDS | |

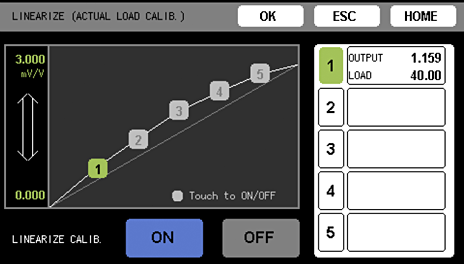

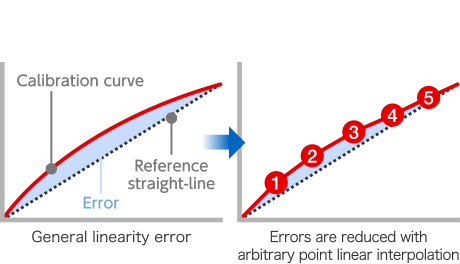

| Linearize function* | Five-point tracking | |

| Accuracy | Linearity | Within 0.01%F.S. ±1digit (when input is 3.2 mV/V) |

| Zero drift | Within 0.5µV/ºC (Input conversion value) | |

| Gain drift | Within 0.005%F.S/ºC | |

| Filter | Low pass | OFF/3/10/30/100/300/1000Hz (Digital filter, -6dB/oct) |

| Moving average | OFF / 2 - 2048 times | |

| Auto digital | Only digital value display(constant judgement) | |

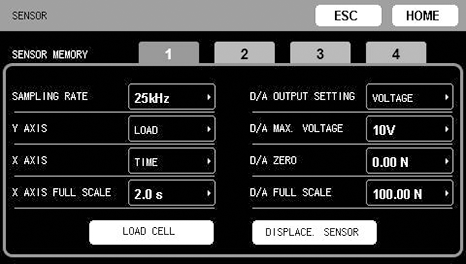

| A/D conversion | Sampling rate | 5000 times per second, 25000 times per second |

| Resolution | 24-bit (binary) | |

| TEDS function | IEEE1451.4 class 2 mix mode interface | |

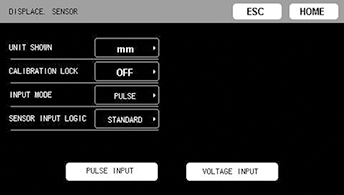

| Pulse type | A/B phase or A phase, differential square wave (RS-422 conformance) |

|---|---|

| Maximum input freq. | 2 MHz |

| Maximum count value | 15,000,000 |

| Calibration method | Equivalent Input / Actual Load |

| Moving average filter | OFF / 2 - 2048 times |

| Power supply for sensor driving | 5V (±10%)、500mA Max. |

| Input voltage range | ±5.2V | |

|---|---|---|

| Calibration | Calibration range | 0 - 5.2V |

| Calibration method | Equivalent Input / Actual Load | |

| Accuracy | Linearity | Within 0.01%F.S. ±1digit (Input ≥3.3V) |

| Zero drift | Within 0.005%F.S/ºC | |

| Gain drift | Within 0.02%F.S/ºC | |

| Filter | Low pass | OFF/10/30/100/300Hz (-6dB/oct) |

| Moving average | OFF / 2~2048 times | |

| A/D conversion | Resolution | 24-bit (binary) |

| Power supply for sensor driving | 12V (±10%), 250mA Max. | |

Device settings

| Power supply | DC 24V (±10%) 13W, AC100-240V (AC adapter is optional) | |

|---|---|---|

| Environment | Temperature | 0ºC - 40ºC (Operating)/-20ºC - 60ºC (Storage) |

| Humidity | 85% RH or less (without condensation) | |

| Dimensions/ Weight | Approx. 114 mm x 96 mm x 140 mm (protrusions not included) / About 960 [g] | |

| Applicable standards | EMC | FCC (class A, To be scheduled) |

| Safety | CE, UL (To be scheduled), UKCA | |

| Display | 4.3 inch LCD color resistive touch panel | |

| Display range | -32000 - +32000 | |

| Language | Japanese / English / Chinese* / Korean* | |

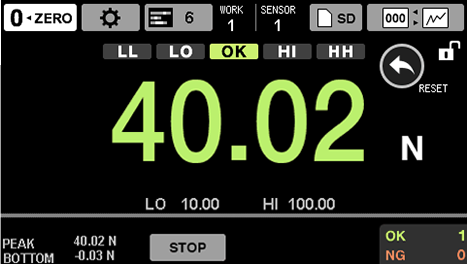

| Screen | Digital load value, Waveform, Archive data, Setting | |

| Waveform | X-axis Time | 80ms/170ms/400ms/800ms/2.0s/4.0s/10.0s/30.0s/60.0s/120.0s |

| Displacement | 2000/4000/6000/8000/10000/15000/20000/30000 | |

| Y-axis | Load (STD) / Load and displacement (biaxially) | |

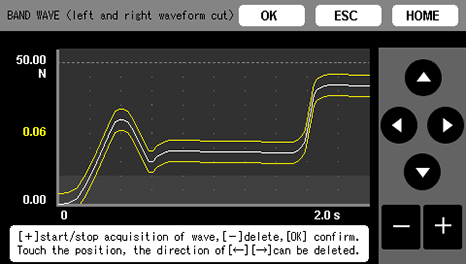

| Comparison waveform | Band judgment | Offset reference band / Designated value band |

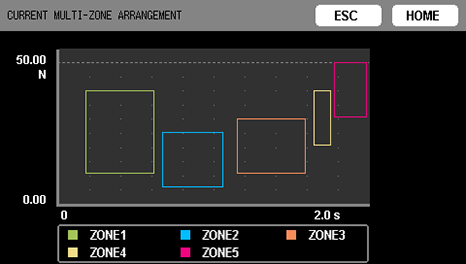

| Multi-zone judgment | Up to 5 judgment zones can be set by device/external signal | |

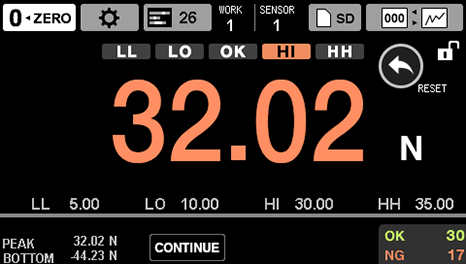

| Comparison judgment | Load: HH / HI / OK / LO / LL Displacement: HI / OK / LO |

|

| Hold setting | Constant comparison, sampling, peak, bottom, peak to peak, maximum/minimum, inflection point and average value | |

| Beep function | Sounding when judgments are not OK (ON / OFF Switchable) | |

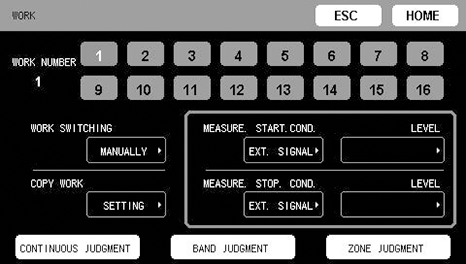

| Measurement work settings | Number of works | 16 (Work can be copied) |

| Switching | External input signal / manual | |

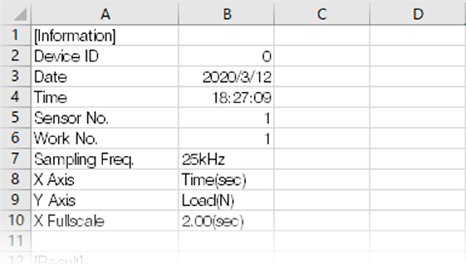

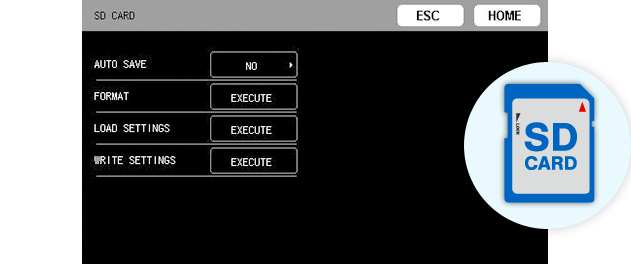

| Data recording | Built-in memory (up to 70) or SD cards | |

| D/A converter | Output range | Isolated, Current (4-20mA), Voltage (-10V - +10V) |

| Conversion rate | Same as A/D converting rate | |

| Resolution | current output: about 1/43000, voltage output: about 1/59000(when set to ±10V) | |

| Impedance | 350Ω or less (Current output) / 2kΩ or more (Voltage output) | |

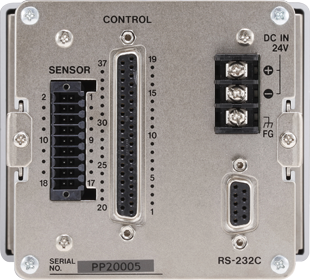

| Communication interface | RS-232C (D-sub 9-pin), USB | |

| Control input/output signal (Photocoupler Insulation) | Input signal | Differential pulse displacement sensor (A phase, B phase), Back light On/Off, Touch panel lock, reset, work select, hold zone select, clear, Judgement On/Off, Measurement Start/End, Preset displacement, Digital zero |

| *Signals are input when shorted/opened (contact or non-contact (transistor, TTL open collector)) between any input terminal and the COM terminal. | ||

| Output signal | Load judgement (HH/HI/OK/LO/LL), Displacement judgement (HI/OK/LO), Load cell abnormal, Measurement Completed, Trigger(1, 2) | |

| *NPN open collector (Sync type) | ||

| *Maximum Current: 20 mA/Voltage: 30 V | ||

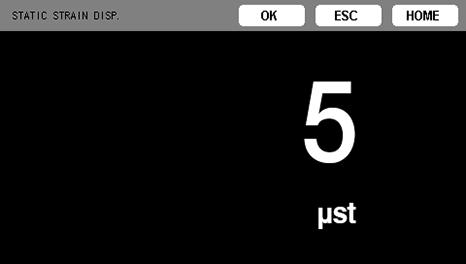

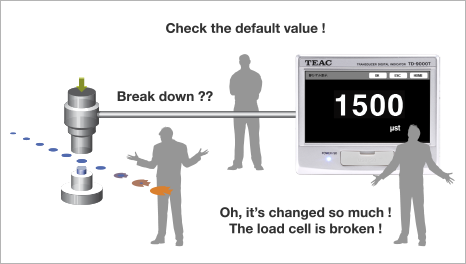

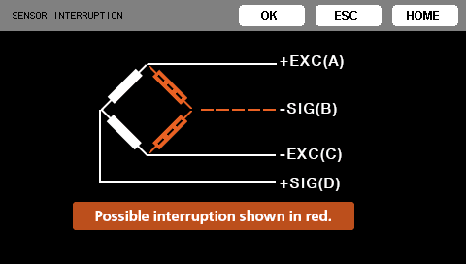

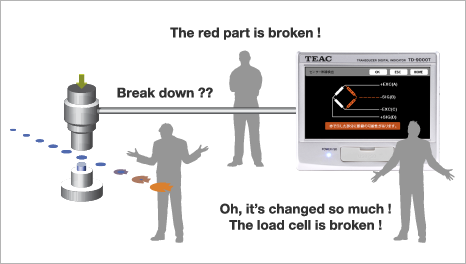

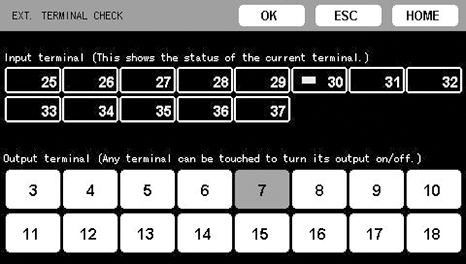

| Check functions | Load cell check (static strain/nterruption detection), contact terminal check | |

| Date and time setting | Date (YYYY/MM/DD, etc.)/time can be set | |

| Recording media | SD/ SDHC(2~32GB, Class 10 recommended) | |

TEAC TD-9000T 商品介紹